Ad Overhead Ambient or Portable. Garys engaging yet professional approach made for a worry-free project completed on time and on budget.

MIG Welding Gas for Stainless Steel Welding.

Stainless steel welding gas. Electrostatic Precipitators Disposable Media and Reverse Jet Cartridge Dust Collectors. Its purpose is to help with the material fusion of the steel. Or maybe even a specialist stainless gas mix such as BOCs Stainshield range of argon helium and carbon dioxide especially for more-exotic stainless steels such as Inconel Hastelloy or Monel alloys.

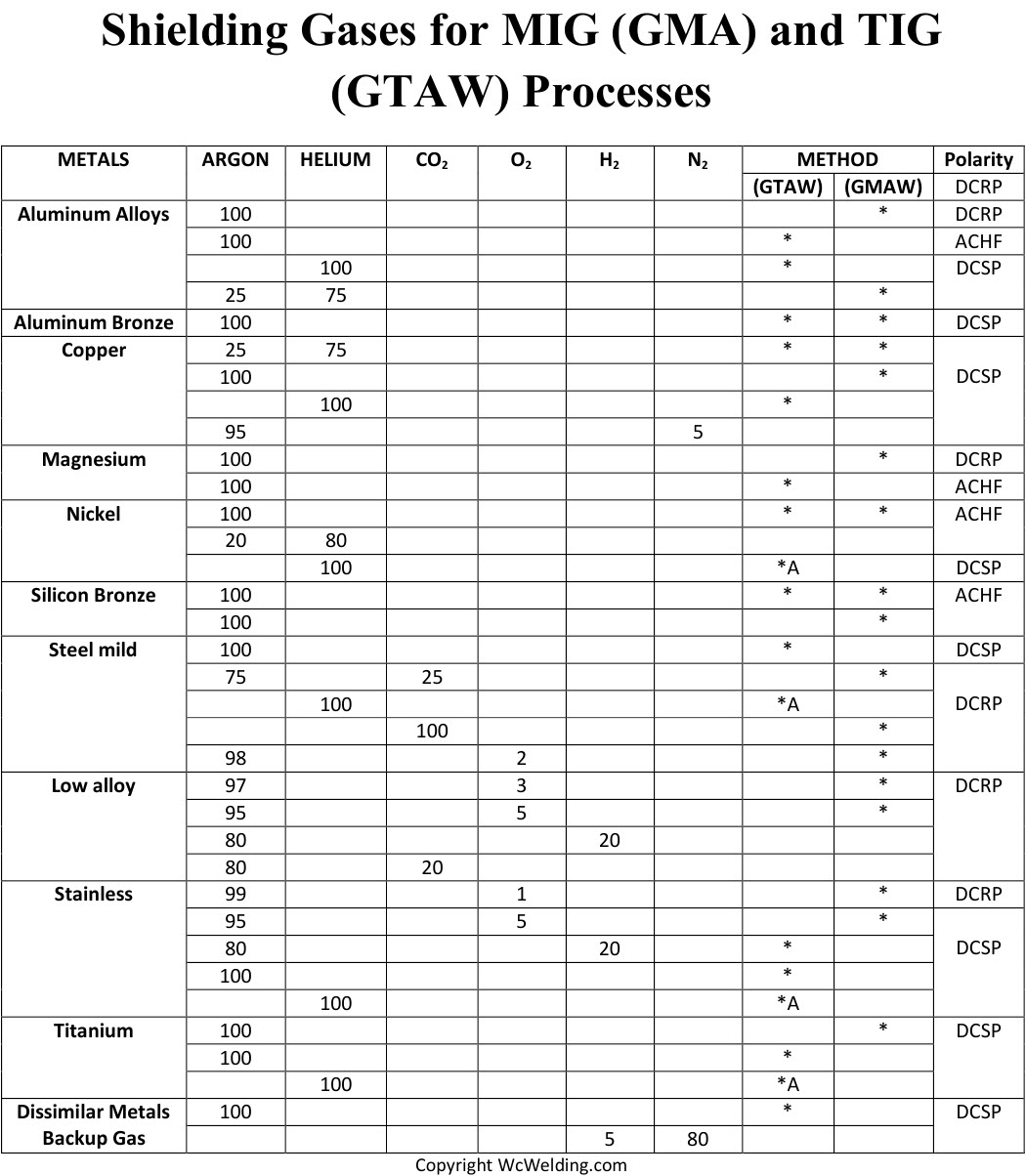

In some cases there is tri-mix shielding gas containing 90 Helium 75 Argon and 25Carbon dioxide. Welding Gas for Stainless Steel While choosing the Shielding gas for MIG welding stainless steel welders usually prefer a mixture consisting of Argon 98 and CO2 2 while some prefer to use the gas mixture of Helium -90 Argon 7 and CO2 2. Flux cored arc welding of stainless steels is becoming increasingly popular as high quality tubular wires become available.

Ideal for fillet welding in the flat and horizontal positions where appearance is critical especially on exposed coated steelwork. This mix of gases isnt suited to stainless steel and if you are welding steel with it it will normally be light gauge steel. Best Welding Method for Stainless Steel.

You wont normally find very much Oxygen in this argon gas mix because otherwise it would burn too hot and argon gas welding is for finer things and. Stainless steel is generally helpful in welding. And it allows your MIG welder to produce the right kind of electrical arc to weld your stainless steel.

As ever correct gas choice matters when MIG welding stainless steel. Chromium is the basic alloy element of all groups of stainless steels. Even though most of the welding machine manufacturers have included a table of materials and voltage settings in the machine it is highly important for you to pick the right kind of gas and electrode wire to be used for MIG welding stainless steel.

The shielding gas can also have an effect on arc stability weld shape and depth of penetration as well as the mechanical properties and metallurgy of stainless steel weldments. Ad Overhead Ambient or Portable. We have an open concept contemporary cabin and chose GAS Welding to manufacture and install stainless and glass railings to add an architectural highlight.

Tri Mix gas 90 Helium 75 Argon 25 Carbon Dioxide protects and shields your weld. Welding with stainless steel produces chromium. Alternative gases that you can use are 98 Argon and 2 Co2 or 98 argon and 2 oxygen mix.

Electrostatic Precipitators Disposable Media and Reverse Jet Cartridge Dust Collectors. You may be using pure argon or a blend of argon and minor gases to improve starting. The best welding processes for stainless steel are as follows.

Stainless steels which require special welding procedures are discussed in later sections. Welding of stainless steel is typically done with C2 or 2 Carbon Dioxide and 98 Argon. Please register or sign in to view prices and order.

MIG Welding Gas. Spot welding might be a good option if you are seeking a more affordable weld type. Youll find more on this further down this post.

The gas shielded processes such as Gas Tungsten Arc Welding GTAW or TIG and Gas Metal Arc Welding GMAW or MIG use shielding gases of a variety of compositions. TIG welding gas tungsten arc welding might be ideal for thin materials. Again many welding supply stores carry their own mixture that can improve the weld quality and ease of welding on stainless steel.

In resistance welding lower current can be used because resistivity is higher. Briefly welders can weld stainless steel with many welding types. Welding stainless steel is a common process which has raised concerns for the working environment.

For stainless steels there are also gases available containing small amounts of hydrogen H2. Less welding heat is required to make a weld because the heat is not conducted away from a joint as rapidly as in carbon steel. While your stainless steel melts in your arc.

However small additions of oxygen O2 or carbon dioxide CO2 are usually needed to stabilize the arc improve the fluidity and improve the quality of the weld deposit. The majority of those steel grades contain nickel. In most cases the gas used will be C2 or 2 Carbon Dioxide and 98 Argon.

Argon or argonhelium mixtures can be used for welding all grades. Gases for all types of stainless steels Welding speed Spatter control Porosity control Fusion Penetration Ease of use Thickness range mm Carbon dioxide 0 to 25 CORGON 25 0 to 25 CRONIGON 2 0 to 25 The greater the number of dots the better the gas performs. We are abslutely delighted with the end product.

2 hydrogen in argon shielding gas Air Products Inomaxx TIG welding gas creates significantly more enhanced welding performance when TIG welding austenitic stainless steel. Welding of stainless steel is typically done with mixture of Argon and Carbon Dioxide gasses that can be as low as 2 carbon Dioxide to as high as 25 carbon Dioxide. In some cases there is tri-mix shielding gas containing 90 Helium 75 Argon and 25Carbon dioxide.

During the welding process chromium is converted to its hexavalent state.